To ensure safe storage of gases and liquids with varying levels of corrosiveness, storage tanks often require internal fluoropolymer linings or coatings. Depending on the chemical properties and working conditions, such as acids, alkalis, or refined substances, different fluoropolymer materials are selected to provide effective corrosion resistance.

- Corrosion resistance

- High purity

- Non-stick

- Low static discharge

- Low friction

- Semiconductor

- Petrochemical

- Pharmaceutical

- Agrochemical

- Lithium battery

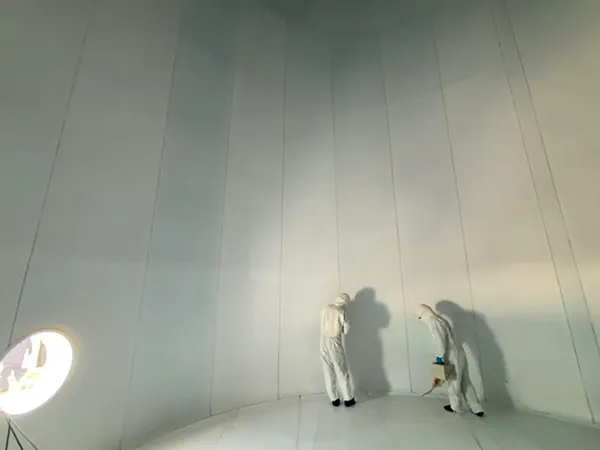

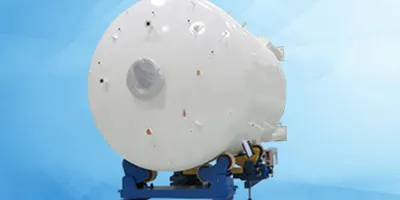

To meet the strict purity and corrosion resistance requirements of semiconductor and electronics applications, storage vessels are lined with high quality imported fluoropolymer sheets such as PTFE, N-PTFE, and PFA. Materials are sourced from trusted brands including Daikin and DuPont.

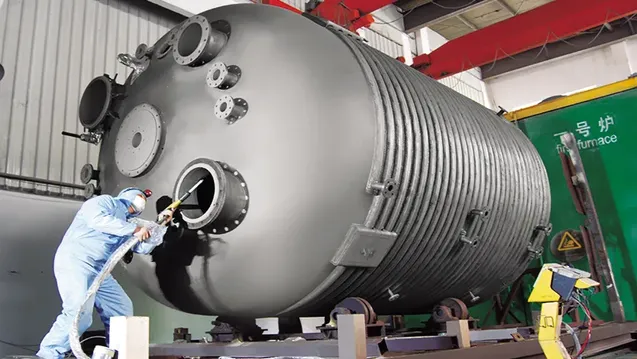

Industrial-grade storage vessels are commonly lined with locally sourced fluoropolymers such as PTFE and PFA. These linings offer corrosion resistance and non-stick performance, making them suitable for handling a wide range of chemicals.

Storage tanks used in general chemical applications are often coated with imported ETFE, PFA, FEP, or ECTFE (from brands like Daikin and DuPont). These coatings offer reliable corrosion resistance, non-stick surfaces, and strong anti-static performance.

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.

- Email: cntsales@hotmail.com

-

- Fluoropolymer Coating We offer customized fluoropolymer coating solutions to protect your equipment More

-

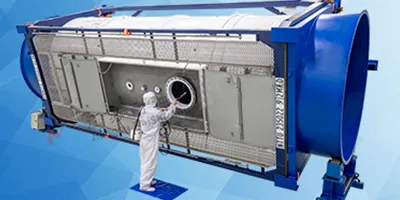

- Fluoropolymer Lining We offer customized fluoropolymer lining solutions to extend the life of your equipment More