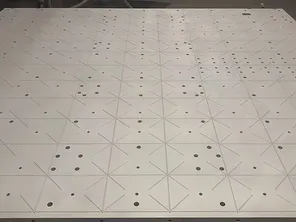

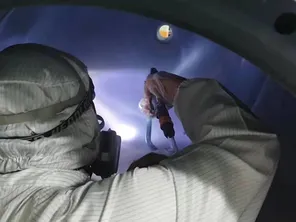

In semiconductor manufacturing, equipment must meet strict purity and stability standards. Our coating and lining services are developed to protect processing equipment from chemical corrosion, surface wear, and unwanted adhesion, ensuring reliable performance in demanding environments. Backed by over two decades of experience, our team works within Class 1,000 and Class 10,000 cleanrooms designed for the treatment of components used in electronic chemical and polymer production. Strict environmental controls help minimize contamination and ensure that coated surfaces meet the purity requirements for chemical storage and reaction stability. The result: reduced metal ion release, improved consistency, and longer conductor manufacturing equipment service life.

- Corrosion resistance

- High purity

- Non-stick surface

- Static control

- Low friction

- Mixing

- Filtration

- Drying

- Mobile tankers

- Storage tanks

- Semiconductor transport and cleaning parts

- Packed towers

- Adsorption resin columns

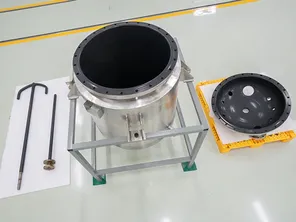

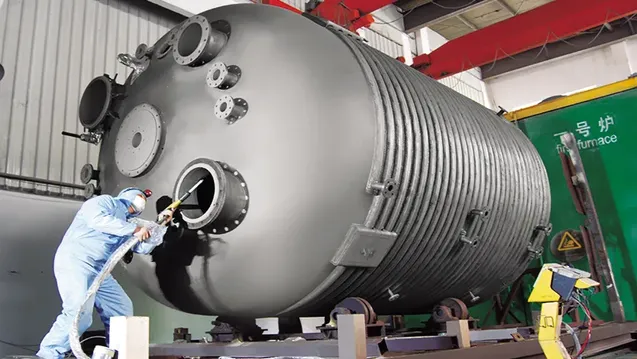

Equipment used in semiconductor manufacturing, such as reactors, preparation tanks, filters, and quartz lift ing manipulator, requires surface protection that meets strict purity and chemical resistance standards. We offer coating and lining services using PFA, ECTFE (F30, Halar), and PVDF, with achievable purity grades ranging from G2 to G5. All coatings are processed in our dedicated Class 1,000 cleanroom, designed for semiconductor applications. This controlled environment helps minimize contamination and ensures stable, high-quality finishes across a variety of equipment types.

| Corrosion Protection Grade | Process Selection | Corrosion Protection Thickness | Typical Color | Raw Material Brand | Purity Grade |

| Fluoropolymer Coating for Semiconductor Manufacturing | PFA high purity coating | 10μm-2000μm | Black/Beige/Transparent… | / | 0.5-1ppb |

| ECTFE (F30,Halar) high purity coating | 0.2mm-1.5mm | Black/Green… | Solvay (USA) | ||

| PVDF coating | 0.2mm-1.5mm | Black/Beige/Transparent… | Arkema (France) | ||

| PFA high purity anti-static coating | 10μm-2000μm | Black/Beige/Transparent… | / |

Examples of Fluoropolymer Coating Applications

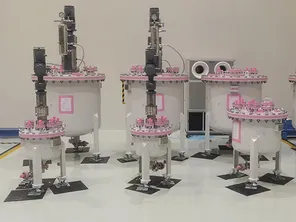

Photoresist preparation vessel

Coated with high-purity PFA to ensure total metal ion content below 1 ppb, with gold ion levels under 0.2 ppb. Conductive PFA is also available, with resistivity ranging from 10⁻⁵ to 10⁻⁹ Ω•cm and purity from 10 ppb to 1 ppb.

PI (Polyimide) reaction vessel

Used in the production of polyimide materials for semiconductor applications. These vessels are coated with high-purity PFA to minimize metal ion contamination, meeting strict purity requirements: total metals below 1 ppb and gold ions below 0.2 ppb.

Double-sided precision polishing machine

Used in applications like semiconductor substrates, transistors, and precision optics. High-purity PFA coating is applied to key components to provide corrosion resistance and reduce metal contamination. Excellent durability against strong acids, alkalis, and organic solvents.

We provide fluoropolymer lining services for various semiconductor manufacturing equipment, including portable containers, vertical and horizontal tanks, and filtration units. Materials such as PFA, ECTFE, and PVDF are used depending on process needs, with purity levels from G3 to G5. Production takes place in our dedicated cleanroom facility, ensuring consistent quality and a high level of cleanliness throughout the lining process.

| Corrosion Protection Grade | Process Selection | Corrosion Protection Thickness | Typical Color | Raw Material Brand | Purity Grade |

| Fluoropolymer Lining for Semiconductor Manufacturing | PTFE (F4) lining | 2mm-5mm | White | Chemours/DuPont (USA) Daikin (Japan) | G3-G5 |

| PFA lining | 1.5mm-4mm | Transparent | |||

| N-PTFE (modified PTFE) lining | 2mm-4mm | White |

Examples of Fluoropolymer Lining Applications

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.

- Email: cntsales@hotmail.com

-

- Fluoropolymer Coating We offer customized fluoropolymer coating solutions to protect your equipment More

-

- Fluoropolymer Lining We offer customized fluoropolymer lining solutions to extend the life of your equipment More