Corrosion and chemical exposure are constant challenges in petrochemical processing. We offer tailored fluoropolymer coating and lining services to protect reactors, tanks, towers, and pipelines used throughout petrochemical operations.

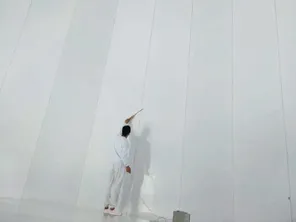

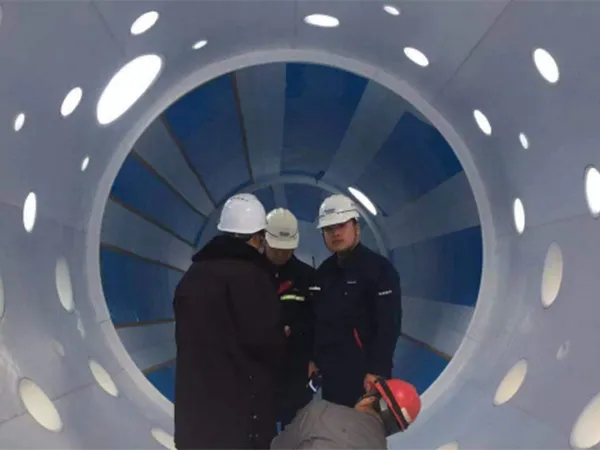

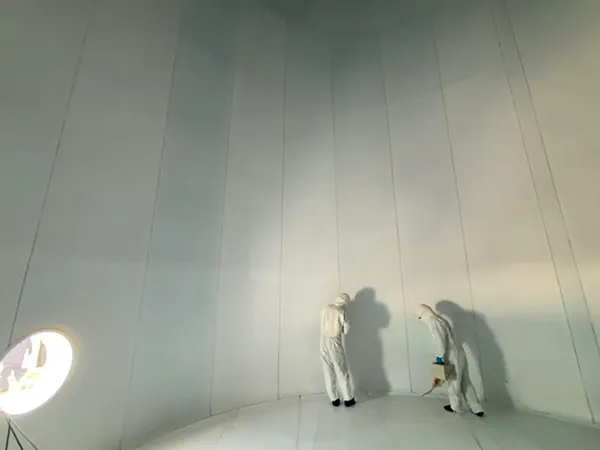

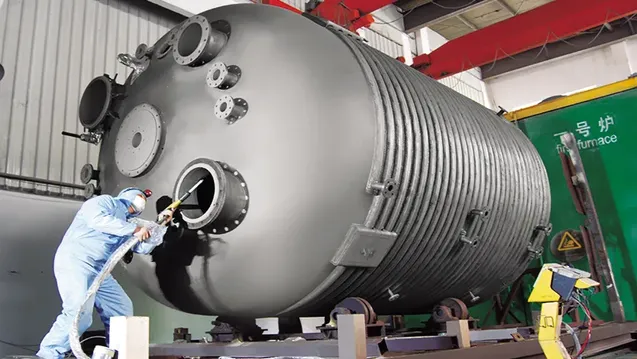

Backed by over 20 years of industry experience, our technical team is capable of handling a wide range of projects in both in-house and on-site environments. Our facility includes 27 curing ovens, one of them being the largest in China (Ø5m × 10m), plus 15 ovens with Ø4.5m capacity, and four smaller units for specialized testing. For large-scale or complex structures, we also provide on-site coating and lining services without equipment size limitations. Production is carried out in multiple dedicated spaces, including a 4000㎡ class 10,000 cleanroom for lining work, a 5000㎡ industrial-grade lining workshop, and six rotomolding units. We also have a class 1,000 coating workshop which supports high-purity and demanding applications.

- Corrosion resistance

- Non-stick properties

- Anti-static performance

- Low friction surface

- Mixing tanks

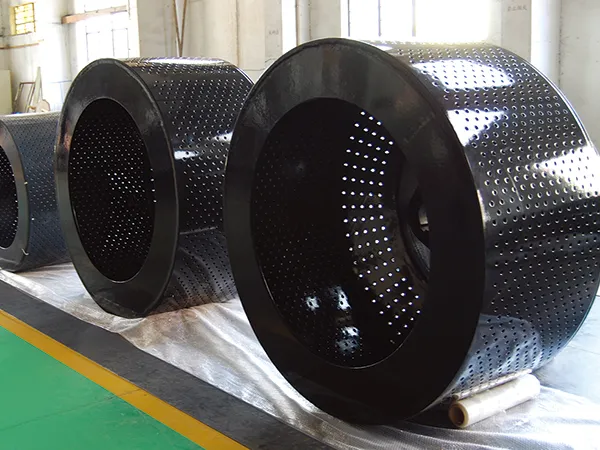

- Filtration systems

- Drying equipment

- Portable containers

- Storage vessels

- Transfer and cleaning parts for semiconductor processes

- Packed towers

- Resin adsorption columns

We provide coating and lining solutions for a wide range of petrochemical processing equipment, including reactors, large storage tanks, portable containers, vertical and horizontal vessels, and filtration units. Depending on application needs, we work with materials such as PFA, PTFE (F4), ECTFE (F30, Halar), ETFE (F40), PVDF, and FEP (F46). For oversized tanks and complex installations, on-site lining is available without limitations on equipment size, ensuring flexibility and reliability in demanding environments.

Fluoropolymer Coating Process

| Corrosion Protection Grade | Process Selection | Corrosion Protection Thickness | Typical Color | Raw Material Brand | Purity Grade |

| Fluoropolymer Coating for Industrial Applications | PTFE (F4) coating | 10μm-70μm | Green/Grey/Black/Brown… | Chemours/DuPont (USA) Daikin (Japan) Solvay (USA) | G1-G2 |

| PFA coating | 10μm-2000μm | Red/Black/White/Grey… | G1-G3 | ||

| FEP (F46) coating | 10μm-1500μm | White/Black/Green… | G1-G2 | ||

| ECTFE (F30,Halar) coating | 0.2mm-1.5mm | White/Black/Green… | G1-G3 | ||

| ETFE (F40) coating | 0.2mm-1.5mm | Blue/Grey/White/Green… | G1-G3 | ||

| PVDF coating | 0.2mm-1.5mm | Beige/Black… | G1-G3 | ||

| PFA anti-static coating | 10μm-2000μm | Red/Black/White/Grey… | G1-G3 | ||

| ETFE (F40) anti-static coating | 0.2mm-1.5mm | Blue/Grey/White/Green… | G1-G3 | ||

| PTFE (F4) anti-static coating | 10μm-70μm | Green/Grey/Black/Brown… | G1-G2 |

Fluoropolymer Lining Process

| Corrosion Protection Grade | Process Selection | Corrosion Protection Thickness | Typical Color | Raw Material Brand | Purity Grade |

| Fluoropolymer Lining for Industrial Applications | PTFE (F4) lining | 2mlm-5mm | White | Chemours/DuPont (USA) Daikin (Japan) Dongyue Group (Shandong,China) | G1-G3 |

| PFA lining | 1.5mm-4mm | Transparent | Chemours/DuPont (USA) Daikin (Japan) Yonghe (Zhejiang,China) | ||

| ECTFE (F30,Halar) lining | 2mm-4mm | Transparent | Solvay (USA) | ||

| PVDF lining | 2mm-4mm | Transparent | Arkema (France) |

Fluoropolymer Coating for Industrial Applications

Fluoropolymer Lining for Industrial Applications

Examples of Fluoropolymer Coating and Lining ApplicationsOn-site processing services are available for large or complex equipment that cannot be easily transported.

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.

- Email: cntsales@hotmail.com

-

- Fluoropolymer Coating We offer customized fluoropolymer coating solutions to protect your equipment More

-

- Fluoropolymer Lining We offer customized fluoropolymer lining solutions to extend the life of your equipment More