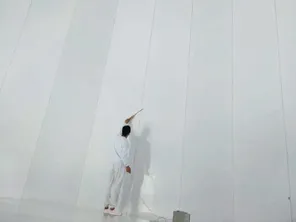

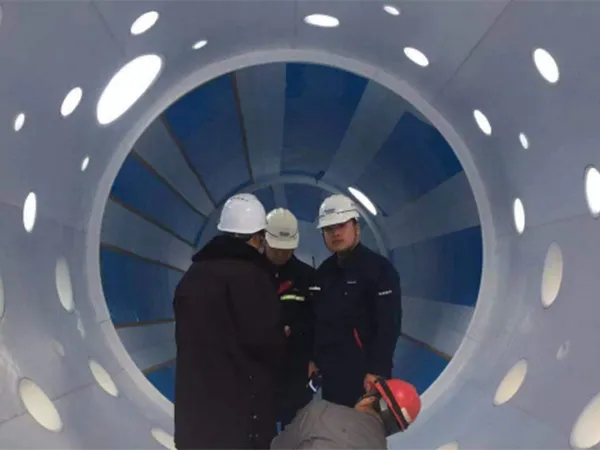

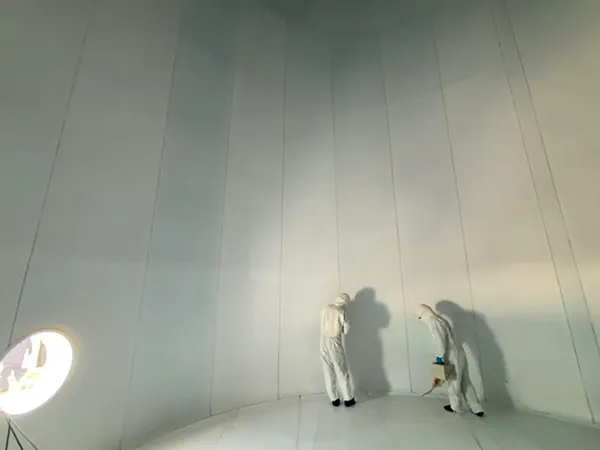

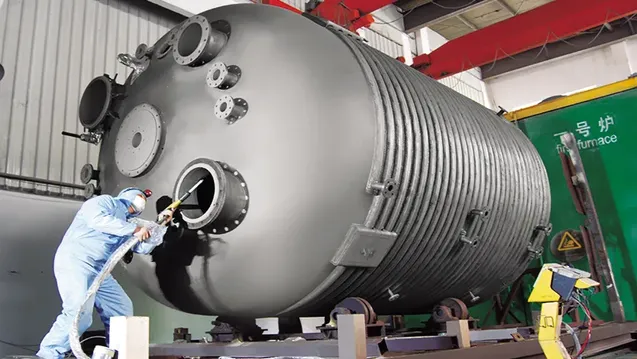

Lithium-ion battery manufacturing relies on equipment that must withstand strong chemical exposure and high-purity requirements. Fluoropolymer coatings and linings help maintain process reliability by minimizing corrosion, contamination, and material degradation. Thanks to our more than 20 years of experience, we have a team capable of delivering tailored solutions for reactors, storage tanks, and mobile containers used in battery production. Our facility includes 27 curing ovens, one of which measures 5 meters in diameter and 10 meters in length, the largest of its kind in China, along with 15 ovens at 4.5 meters and four small electric models for pilot applications. We also operate a 1000-class cleanroom for precision coating, a 4000㎡ 10,000-class cleanroom for lining, and a 5000㎡ industrial-grade lining workshop. On-site application services are available for large or difficult-to-transport equipment.

- Corrosion resistance

- Anti-stick surface

- Electrostatic dissipation

- Low friction

- Mixing

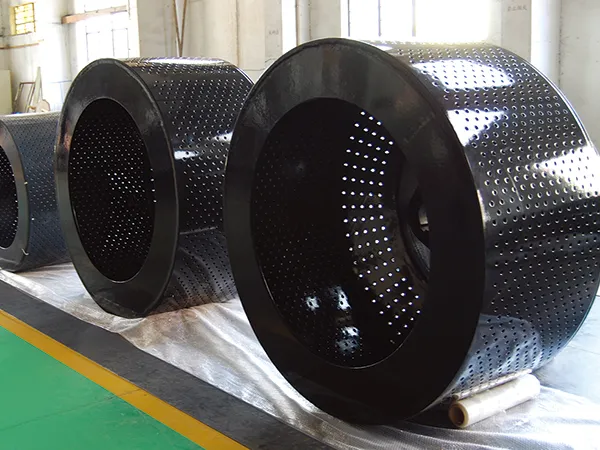

- Filtration

- Drying

- Mobile containers

- Storage tanks

- Semiconductor cleaning components

- Columns

- Adsorption resin colum

Equipment used in lithium battery production often requires chemical resistance and high-purity surface protection. To meet these needs, we apply PFA, PTFE (F4), ECTFE (F30, Halar), ETFE (F40), PVDF, and FEP (F46) coatings and linings across a wide range of equipment, including reactors, large storage tanks, mobile containers, and filtration units. When equipment size makes transport difficult, on-site application is available without limitations.

Fluoropolymer Coating Process

| Corrosion Protection Grade | Process Selection | Corrosion Protection Thickness | Typical Color | Raw Material Brand | Purity Grade |

| Fluoropolymer Coating for Industrial Applications | PTFE (F4) coating | 10μm-70μm | Green/Grey/Black/Brown… | Chemours/DuPont (USA) Daikin (Japan) Solvay (USA) | G1-G2 |

| PFA coating | 10μm-2000μm | Red/Black/White/Grey… | G1-G3 | ||

| FEP (F46) coating | 10μm-1500μm | White/Black/Green… | G1-G2 | ||

| ECTFE (F30,Halar) coating | 0.2mm-1.5mm | White/Black/Green… | G1-G3 | ||

| ETFE (F40) coating | 0.2mm-1.5mm | Blue/Grey/White/Green… | G1-G3 | ||

| PVDF coating | 0.2mm-1.5mm | Beige/Black… | G1-G3 | ||

| PFA anti-static coating | 10μm-2000μm | Red/Black/White/Grey… | G1-G3 | ||

| ETFE (F40) anti-static coating | 0.2mm-1.5mm | Blue/Grey/White/Green… | G1-G3 | ||

| PTFE (F4) anti-static coating | 10μm-70μm | Green/Grey/Black/Brown… | G1-G2 |

Fluoropolymer Lining Process

| Corrosion Protection Grade | Process Selection | Corrosion Protection Thickness | Typical Color | Raw Material Brand | Purity Grade |

| Fluoropolymer Lining for Industrial Applications | PTFE (F4) lining | 2mlm-5mm | White | Chemours/DuPont (USA) Daikin (Japan) Dongyue Group (Shandong,China) | G1-G3 |

| PFA lining | 1.5mm-4mm | Transparent | Chemours/DuPont (USA) Daikin (Japan) Yonghe (Zhejiang,China) | ||

| ECTFE (F30,Halar) lining | 2mm-4mm | Transparent | Solvay (USA) | ||

| PVDF lining | 2mm-4mm | Transparent | Arkema (France) |

Fluoropolymer Coating for Industrial Applications

Fluoropolymer Lining for Industrial Applications

Examples of Fluoropolymer Coating and Lining ApplicationsOn-site processing services are available for large or complex equipment that cannot be easily transported.

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.

- Email: cntsales@hotmail.com

-

- Fluoropolymer Coating We offer customized fluoropolymer coating solutions to protect your equipment More

-

- Fluoropolymer Lining We offer customized fluoropolymer lining solutions to extend the life of your equipment More