We have over 20 years of experience in high-purity fluoropolymer coating and lining, supported by in-house cleanroom facilities. Coating impurity levels are controlled below 1PPb, and linings below 5PP, meeting the strict purity demands of semiconductor and precision manufacturing industries.

High purity fluoropolymer coatings are ideal for industries that demand strict contamination control and consistent chemical performance, such as:

- Semiconductor processing equipment

- Active pharmaceutical ingredient (API) production

Common applications focus on maintaining purity and equipment integrity in various process steps, including:

- Blending operations

- Precision filtration

- Controlled drying

- Mobile chemical transport tanks

- Storage vessels

- Semiconductor part cleaning and transfer

- Packed towers

- Resin columns

Our high purity coating is available in two types: liquid and powder. Liquid fluoropolymer coating is typically applied manually and used on complex areas like grooves or sharp corners where powder coating can't form a uniform film. It requires more precise control over thickness and is not compatible with standard mechanical spray systems.

Powder coating is more efficient for large surfaces and is usually applied through electrostatic spraying. Although it's faster for mass processing, the film thickness is slightly harder to control compared to liquid coating.

With over 20 years of experience in high purity coating, we operate a certified ISO 9001 and ISO 14000 facility equipped with a Class 1000 cleanroom for spray processing. Our coatings are approved by Chemours, Solvay, and Daikin. We ensure ultra-low metal ion contamination, total metal impurities can be controlled below 1 ppb.

Metallic Impurity Levels in Finished Coating (Performance Data) Metal Content Evaluation of High-Purity Coating Over 12 Days (unit: ppb)

| 1 day | 2 days | 3 days | 4 days | 5 days | 6 days | 7 days | 8 days | 9 days | 10 days | 11 days | 12 days | |

| Li | 0 | 0 | 0.000 | 0.000 | 0.000 | 0.001 | 0.001 | 0.001 | 0.001 | 0.000 | 0.001 | 0.001 |

| Na | 0.0336 | 0.0181 | 0.037 | 0.070 | 0.102 | 0.122 | 0.142 | 0.106 | 0.176 | 0.190 | 0.106 | 0.176 |

| Mg | 0.0249 | 0.0281 | 0.002 | 0.005 | 0.002 | 0.004 | 0.005 | 0.001 | 0.001 | 0.002 | 0.001 | 0.001 |

| Al | 0.0304 | 0.0359 | 0.004 | 0.008 | 0.007 | 0.002 | 0.002 | 0.002 | 0.001 | 0.001 | 0.002 | 0.001 |

| K | 0.0071 | 0.0052 | 0.005 | 0.007 | 0.008 | 0.022 | 0.023 | 0.006 | 0.014 | 0.013 | 0.006 | 0.014 |

| Ca | 0.1123 | 0.0512 | 0.020 | 0.023 | 0.022 | 0.024 | 0.022 | 0.016 | 0.021 | 0.025 | 0.016 | 0.021 |

| Ti | 0.0019 | 0.0009 | 0.001 | 0.001 | 0.002 | 0.001 | 0.001 | 0.001 | 0.001 | 0.000 | 0.001 | 0.001 |

| V | 0.0006 | 0.0004 | 0.001 | 0.001 | 0.001 | 0.000 | 0.000 | 0.001 | 0.001 | 0.000 | 0.001 | 0.001 |

| Cr | 0.0039 | 0.0032 | 0.049 | 0.037 | 0.109 | 0.062 | 0.013 | 0.000 | 0.011 | 0.037 | 0.000 | 0.011 |

| Mn | 0.0159 | 0.0104 | 0.003 | 0.003 | 0.007 | 0.003 | 0.002 | 0.001 | 0.001 | 0.003 | 0.001 | 0.001 |

| Fe | 0.0871 | 0.0567 | 0.090 | 0.169 | 0.087 | 0.065 | 0.120 | 0.045 | 0.058 | 0.104 | 0.045 | 0.058 |

| Co | 0.0012 | 0.0006 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.000 | 0.001 | 0.001 |

| Ni | 0.0249 | 0.0171 | 0.212 | 0.096 | 0.214 | 0.045 | 0.033 | 0.037 | 0.009 | 0.073 | 0.037 | 0.009 |

| Cu | 0.0044 | 0.0026 | 0.021 | 0.025 | 0.030 | 0.020 | 0.018 | 0.055 | 0.055 | 0.037 | 0.055 | 0.055 |

| Zn | 0.1046 | 0.0813 | 0.014 | 0.030 | 0.037 | 0.048 | 0.055 | 0.087 | 0.087 | 0.075 | 0.087 | 0.087 |

| As | 0.0006 | 0.0006 | 0.003 | 0.002 | 0.002 | 0.003 | 0.003 | 0.004 | 0.002 | 0.003 | 0.004 | 0.002 |

| Zr | 0.0004 | 0.0002 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Mo | 0.0021 | 0.0013 | 0.002 | 0.003 | 0.002 | 0.002 | 0.003 | 0.000 | 0.000 | 0.003 | 0.000 | 0.000 |

| Ag | 0.0001 | 0.0003 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | 0.001 |

| Cd | 0 | 0 | 0.005 | 0.004 | 0.003 | 0.009 | 0.006 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Sn | 0.0051 | 0.0021 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.004 | 0.000 | 0.000 | 0.004 | 0.000 |

| Ba | 0.000 | 0.000 | 0.000 | 0.000 | 0.035 | 0.000 | 0.000 | 0.000 | 0.001 | 0.001 | 0.000 | 0.001 |

| Ta | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| W | 0.0028 | 0.0026 | 0.000 | 0.001 | 0.000 | 0.000 | 0.000 | 0.020 | 0.000 | 0.000 | 0.020 | 0.000 |

| Pt | 0.0003 | 0 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Au | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Pb | 0.0003 | 0.0004 | 0.001 | 0.001 | 0.000 | 0.001 | 0.001 | 0.001 | 0.000 | 0.003 | 0.001 | 0.000 |

| Si | 0.7387 | 0.6761 | 0.676 | 0.643 | 0.001 | 0.001 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | 0.000 |

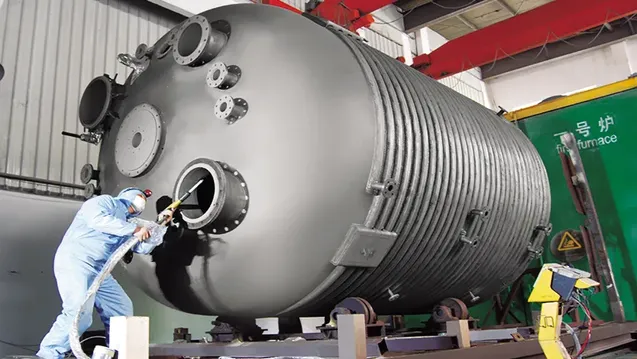

Our high-purity fluoropolymer lining options mainly include two structures: chemically treated smooth sheets and fiberglass-reinforced composite plates. Materials used cover PFA-backed fiberglass plates, modified PTFE-backed fiberglass plates, modified PTFE smooth sheets, standard PTFE sheets, and ECTFE fiberglass composite plates. For cylindrical sections, linings are applied using automated welding systems. For circular seams and nozzles, manual welding is used to ensure precision in complex areas.

We use fluoropolymer lining materials from globally recognized suppliers such as Chemours (DuPont), Solvay, and Daikin. Lining work is carried out in our Class 10,000 cleanroom facilities. Finished linings meet high purity standards, with total metal impurities controlled below 5 PPT.

High Purity Lining Coating Metal Impurity Composition Table

| Analyzed elements | Unit | Sample B analysis | Finished sample B | ||||

| May 25th | June 8th | June 16th | May 25th | Before immersion | |||

| Trace cation content (max) | Lithium (Li) ≤ | ppt | 0.225 | 0.063 | 0.043 | 0.017 | 0.114 |

| Beryllium (Be) ≤ | ppt | 0.085 | 0.098 | 0.028 | 0.057 | 0.05 | |

| Boron (B) ≤ | ppt | 0.899 | 0.773 | 0.018 | 0.616 | 0.155 | |

| Sodium (Na) ≤ | ppt | 0.788 | 0.507 | 0.559 | 0.197 | 0.191 | |

| Magnesium (Mg) ≤ | ppt | 0.105 | 0.582 | 0.555 | 0.501 | 0.085 | |

| Aluminum (Al) ≤ | ppt | 0.082 | 0.766 | 0.433 | 0.258 | 0.044 | |

| Silicon (Si) ≤ | ppt | 0.064 | 0.272 | 0.024 | 0.198 | 0.396 | |

| Phosphorus (P) ≤ | ppt | 0.025 | 0.292 | 0.987 | 0.284 | 0.036 | |

| Potassium (K) ≤ | ppt | 0.114 | 0.421 | 0.347 | 0.069 | 0.363 | |

| Calcium (Ca) ≤ | ppt | 0.57 | 0.171 | 0.781 | 0.522 | 0.128 | |

| Titanium (Ti) ≤ | ppt | 0.073 | 0.18 | 0.053 | 0.073 | 0.061 | |

| Vanadium (V) ≤ | ppt | 0.086 | 0.075 | 0.048 | 0.043 | 0.025 | |

| Chromium (Cr) ≤ | ppt | 0.066 | 0.764 | 0.172 | 0.472 | 0.04 | |

| Manganese (Mn) ≤ | ppt | 0.504 | 0.104 | 0.199 | 0.11 | 0 | |

| Iron (Fe) ≤ | ppt | 0.469 | 0.362 | 0.141 | 0.613 | 0.034 | |

| Cobalt (Co) ≤ | ppt | 0.489 | 0.859 | 0.091 | 0.083 | 0 | |

| Nickel (Ni) ≤ | ppt | 0.248 | 0.109 | 0.126 | 0.65 | 0.024 | |

| Copper (Cu) ≤ | ppt | 0.227 | 0.11 | 0.188 | 0.688 | 0.104 | |

| Zinc (Zn) ≤ | ppt | 0.188 | 0.037 | 0.112 | 0.137 | 0.377 | |

| Gallium (Ga) ≤ | ppt | 0.035 | 0.018 | 0.037 | 0.029 | 0.04 | |

| Germanium (Ge) ≤ | ppt | 0.277 | 0.173 | 0.364 | 0.45 | 0.18 | |

| Arsenic (As) ≤ | ppt | 0.014 | 0.178 | 0.735 | 0.595 | 0.183 | |

| Strontium (Sr) ≤ | ppt | 0.505 | 0.19 | 0.151 | 0.031 | 0.011 | |

| Zirconium (Zr) ≤ | ppt | 0.065 | 0.033 | 0.066 | 0.045 | 0.029 | |

| Niobium (Nb) ≤ | ppt | 0.003 | 0.006 | 0.016 | 0.056 | 0.068 | |

| Molybdenum (Mo) ≤ | ppt | 0.139 | 0.216 | 0.109 | 0.108 | 0.055 | |

| Silver (Ag) ≤ | ppt | 0.342 | 0.256 | 0.295 | 0.258 | 0.191 | |

| Cadmium (Cd) ≤ | ppt | 0.071 | 0.047 | 0.075 | 0.027 | 0.036 | |

| Indium (In) ≤ | ppt | 0.011 | 0.011 | 0.004 | 0.015 | 0.005 | |

| Tin (Sn) ≤ | ppt | 0.16 | 0.247 | 0.58 | 0.232 | 0.178 | |

| Antimony (Sb) ≤ | ppt | 0.358 | 0.215 | 0.396 | 0.307 | 0.007 | |

| Barium (Ba) ≤ | ppt | 0.285 | 0.091 | 0.369 | 0.343 | 0.09 | |

| Tantalum (Ta) ≤ | ppt | 0 | 0 | 0 | 0 | 0.023 | |

| Platinum (Pt) ≤ | ppt | 0.157 | 0.96 | 0.272 | 0.483 | 0.107 | |

| Gold (Au) ≤ | ppt | 0.11 | 0.235 | 0.23 | 0.554 | 0.111 | |

| Mercury (Hg) ≤ | ppt | 0.159 | 0.207 | 0.158 | 0.16 | 0.222 | |

| Thallium (Tl) ≤ | ppt | 0.701 | 0.163 | 0.122 | 0.148 | 0.167 | |

| Lead (Pb) ≤ | ppt | 0.216 | 0.099 | 0.178 | 0.177 | 0.175 | |

| Bismuth (Bi) ≤ | ppt | 0.018 | 0.072 | 0.012 | 0.025 | 0.16 | |

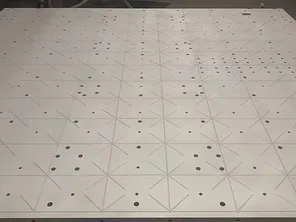

Examples of Fluoropolymer Lining Applications

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.

- Email: cntsales@hotmail.com

-

- Fluoropolymer Coating We offer customized fluoropolymer coating solutions to protect your equipment More

-

- Fluoropolymer Lining We offer customized fluoropolymer lining solutions to extend the life of your equipment More