We offer reliable non-stick coating solutions with excellent thermal stability. Our fluoropolymer coatings perform consistently from –190°C to 260°C, withstanding peaks up to 320°C without becoming brittle or melting—even in thin layers.

Our non-stick coatings are applied using PTFE (F4), PFA, and FEP (F46), with typical thicknesses ranging from 10 to 70 μm. For specific applications, coatings can reach up to 250 μm. These coating materials are electrostatically applied and sintered at high temperatures. The non-stick properties of the finished layer can be attributed to several key factors, which will be detailed below.

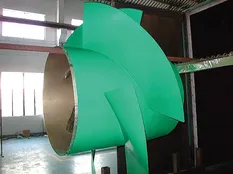

Benefits of non-stick coatings for petrochemical equipment and custom molds

- For processing equipment, the non-stick surface helps maintain cleanliness during operation, reducing manual cleaning time and supporting more efficient workflows.

- For molds, it allows consistent release of finished parts, helping to reduce defects and material waste.

- These coatings can replace traditional release agents, minimizing additional costs and environmental concerns while avoiding disruption of rubber vulcanization or bonding processes.

- Prevents buildup of rubber particles on mold surfaces, which means less downtime for cleaning, reduced tool wear, and more stable energy consumption.

- Creates smooth and uniform surface finishes on final products, which helps improve product appearance and consistency.

ChiNaite has over 20 years of experience in coating and lining services, supported by ISO 9001 and ISO 14000 certifications. We use fluoropolymers officially authorized by Chemours (DuPont), Solvay, and Daikin. Our Class 1,000 cleanroom ensures coating purity, keeping total metal impurities below 1 ppb.

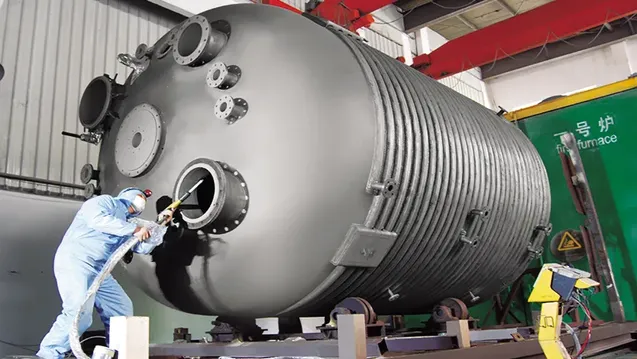

We work with sectors that require high performance in chemical resistance, purity, and process reliability:

- Semiconductor manufacturing

- Oil refining and petrochemical processing

- Pharmaceutical production

- Agrochemical processing

- Lithium battery material handling

From process tanks to precision components, our coatings and linings are applied in:

- Mixing systems and filtration equipment

- Dryers and storage vessels

- Mobile containers and transport tanks

- Semiconductor cleaning and transfer units

- Towers and adsorption resin columns

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.

- Email: cntsales@hotmail.com

-

- Fluoropolymer Coating We offer customized fluoropolymer coating solutions to protect your equipment More

-

- Fluoropolymer Lining We offer customized fluoropolymer lining solutions to extend the life of your equipment More