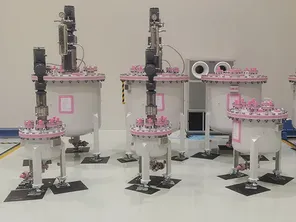

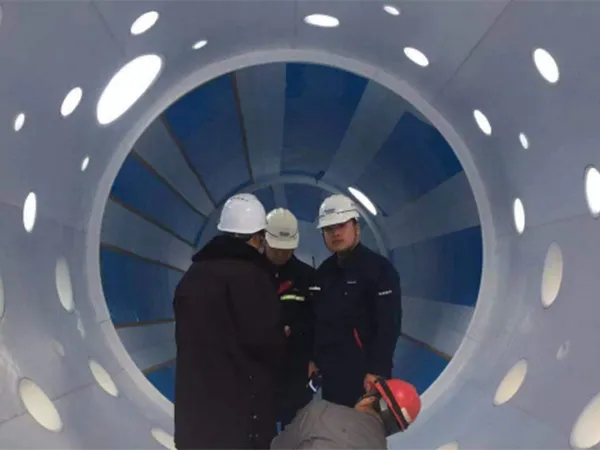

We provide specialized fluoropolymer coating and lining solutions for pharmaceutical equipment to prevent corrosion, surface wear, and product sticking during production. Backed by over 20 years of hands-on experience, our team operates within ISO Class 1,000 and 10,000 cleanrooms carefully designed for pharmaceutical processing, with reinforced controls to reduce contamination risks.

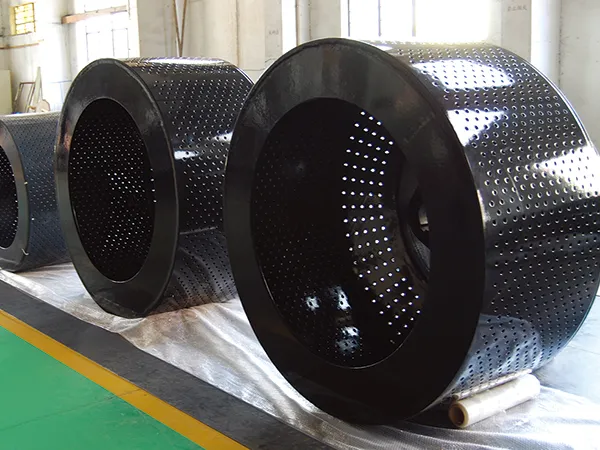

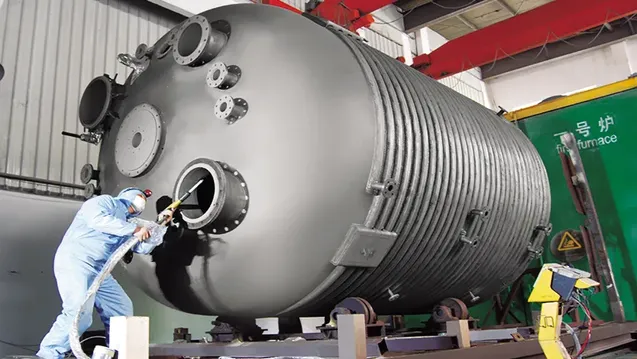

We support pharmaceutical operations with corrosion-resistant, non-stick solutions using materials like PFA, PTFE, ECTFE, ETFE, PVDF, and FEP. These fluoropolymers are applied to equipment such as reactors, vertical and horizontal tanks, mobile containers, and filters, ensuring consistent chemical behavior and minimizing metal ion contamination throughout storage and processing.

Decades of experience have shaped our expertise in adapting to complex pharmaceutical requirements while maintaining the reliability and quality our clients depend on.

- Corrosion resistance

- High purity

- Non-stick surface

- Anti-static properties

- Low friction

- Mixing processes

- Filtration systems

- Drying units

- Mobile transfer tanks

- Storage vessels

- Semiconductor cleaning parts

- Packed towers

- Resin adsorption columns

Fluoropolymer Coating Process

| Corrosion Protection Grade | Process Selection | Corrosion Protection Thickness | Typical Color | Raw Material Brand | Purity Grade |

| Fluoropolymer Coating for Industrial Applications | PTFE (F4) coating | 10μm-70μm | Green/Grey/Black/Brown… | Chemours/DuPont (USA) Daikin (Japan) Solvay (USA) | G1-G2 |

| PFA coating | 10μm-2000μm | Red/Black/White/Grey… | G1-G3 | ||

| FEP (F46) coating | 10μm-1500μm | White/Black/Green… | G1-G2 | ||

| ECTFE (F30,Halar) coating | 0.2mm-1.5mm | White/Black/Green… | G1-G3 | ||

| ETFE (F40) coating | 0.2mm-1.5mm | Blue/Grey/White/Green… | G1-G3 | ||

| PVDF coating | 0.2mm-1.5mm | Beige/Black… | G1-G3 | ||

| PFA anti-static coating | 10μm-2000μm | Red/Black/White/Grey… | G1-G3 | ||

| ETFE (F40) anti-static coating | 0.2mm-1.5mm | Blue/Grey/White/Green… | G1-G3 | ||

| PTFE (F4) anti-static coating | 10μm-70μm | Green/Grey/Black/Brown… | G1-G2 |

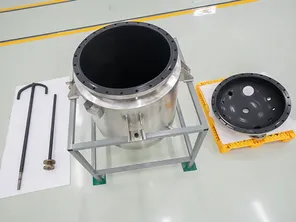

Fluoropolymer Lining Process

| Corrosion Protection Grade | Process Selection | Corrosion Protection Thickness | Typical Color | Raw Material Brand | Purity Grade |

| Fluoropolymer Lining for Industrial Applications | PTFE (F4) lining | 2mlm-5mm | White | Chemours/DuPont (USA) Daikin (Japan) Dongyue Group (Shandong,China) | G1-G3 |

| PFA lining | 1.5mm-4mm | Transparent | Chemours/DuPont (USA) Daikin (Japan) Yonghe (Zhejiang,China) | ||

| ECTFE (F30,Halar) lining | 2mm-4mm | Transparent | Solvay (USA) | ||

| PVDF lining | 2mm-4mm | Transparent | Arkema (France) |

Fluoropolymer Lining for Industrial Applications

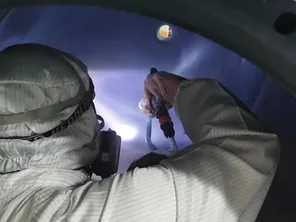

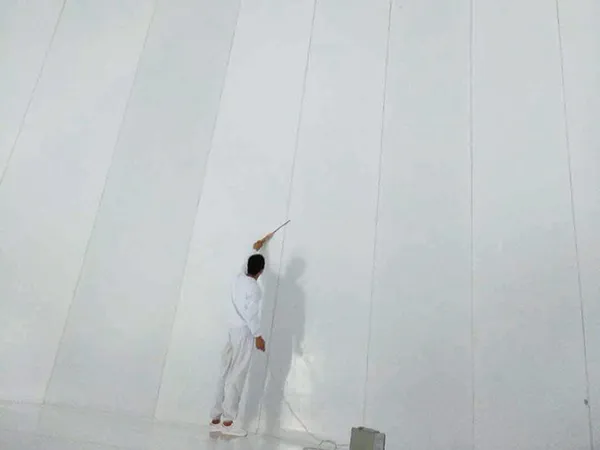

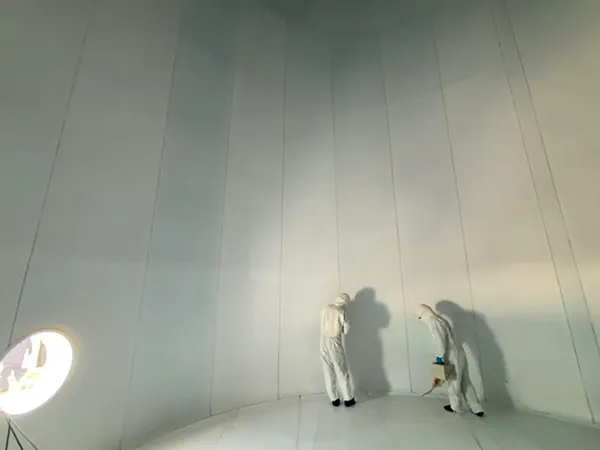

In cases where transportation isn’t feasible or equipment has unique installation constraints, on-site application becomes the most efficient option. We’re fully equipped to handle coating and lining work directly at your facility, ensuring durability and precision from start to finish.

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.

- Email: cntsales@hotmail.com

-

- Fluoropolymer Coating We offer customized fluoropolymer coating solutions to protect your equipment More

-

- Fluoropolymer Lining We offer customized fluoropolymer lining solutions to extend the life of your equipment More