Backed by over 20 years of experience, we provide high-purity fluoropolymer coatings for semiconductor equipment to enhance corrosion resistance, improve yield, and reduce production costs.

Semiconductor transfer and cleaning parts are important for maintaining product quality throughout the manufacturing process. They are used to remove impurities such as particles, oxide layers, metal contamination, organics, sacrificial layers, and polishing residues from wafer production, packaging, and testing stages. If not properly cleaned, these contaminants can lower yield rates, compromise chip performance, and increase production costs.

- Corrosion resistance

- High purity

- Anti-static

- Low friction

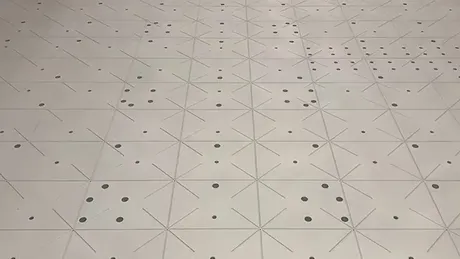

Wafer transfer robot

Coated with high-cleanliness fluoropolymer to prevent metal ion contamination during wafer transfer. Coating can also be applied on ceramic substrates. Anti-static options are available to meet specific ESD protection needs.

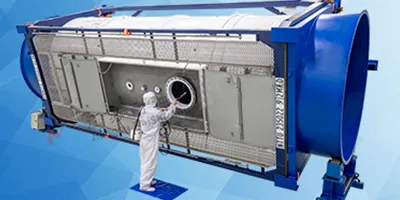

Double-sided precision polishing machine

Used in applications like semiconductor substrates, transistors, and precision optics. High-purity PFA coating is applied to key components to provide corrosion resistance and reduce metal contamination. Excellent durability against strong acids, alkalis, and organic solvents.

Quartz lifting manipulator

Protects quartz and similar substrates from chemical exposure, including hydrofluoric acid. The coating offers excellent hydrophobic and oleophobic properties, minimizing contamination from cleaning fluids. Suitable for temperatures from -180 °C to 260 °C.

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.

- Email: cntsales@hotmail.com

-

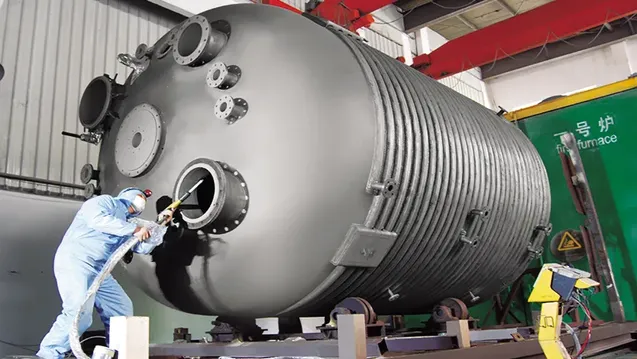

- Fluoropolymer Coating We offer customized fluoropolymer coating solutions to protect your equipment More

-

- Fluoropolymer Lining We offer customized fluoropolymer lining solutions to extend the life of your equipment More