Materials such as silicon carbide, graphite, and various alloys are often used in heat exchangers, but each comes with its own set of challenges, whether it’s brittleness, limited corrosion resistance, or high production costs.

Fluoropolymer sintering provides a more balanced and reliable option. It resists a wide range of aggressive chemicals, including fluorides and chlorides, and helps improve equipment lifespan. This coating process offers a practical solution for replacing metal alloys while lowering maintenance costs and production risks.

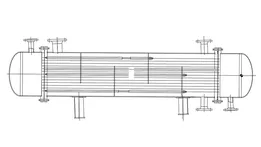

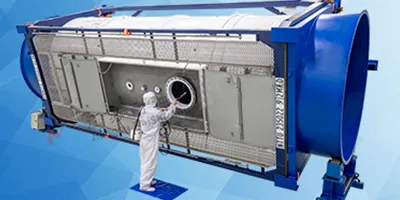

Fluoropolymer-Lined Heat Exchangers Using Sintering Technology

- Corrosion Resistance Range

Suitable for media with pH 1–14, including fluorides, chlorides, bromides, iodides, alkalis, and various organic solvents. - Special Treatment

In demanding working environments, a mesh layer is added before sintering to enhance permeability resistance under high temperatures. - Sintering Process

Grinding and smoothing → degreasing → grit blasting → surface cleaning → primer application → sintering with heat retention → multiple topcoat layers → repeated sintering and curing. - Coating Thickness

Standard thickness: 0.5 mm – 1 mm

Enhanced thickness: 1.8 mm – 2.2 mm - Inspection & Testing

Includes adhesion test, Holiday spark test, coating thickness testing, visual inspection, and vacuum integrity check. - Performance

Covers a wide pH range (1–14), resists aggressive media like fluorinated compounds and chlorinated solvents, tolerates high and low temperatures, and performs well under absolute vacuum. Thermal conductivity reaches 85% of glass-lined steel. The coating is repairable if damaged. Recommended operating temperature: -190°C to 260°C. - Applications

Widely used in sectors such as pesticide and dye intermediates, fine chemicals, fluorochemicals, flue gas desulfurization, pharmaceutical ingredients, and battery materials. Compatible with GMP environments and FDA non-toxicity certification is available upon request.

Horizontal heat exchanger

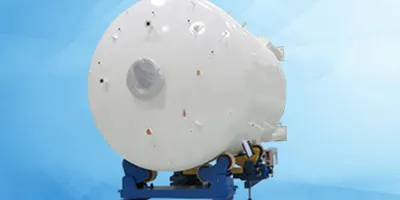

Vertical heat exchanger

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.

- Email: cntsales@hotmail.com